As I wrote before the new track plan(already layed) is arranged for computer control .

But what is computer control ?

It is a series off connected devices from train to the computer in order them to communicate to each other .

The computer generates the commands which are transfered through connction dvice to the command station and then to the rails and finally to the dcc decoder inside the locomotive.The locomotive generates current draw that is tracked on the tracks using the feedback device which sends info back to the Command station which also sends feedback back to the computer.

Finally the computer arranges its choices according to the feedback and the saved preferences (loco proirity etc)

I chose thse solution of Lenz electronics which provides stable , clear and efficient result .

Moreover not to mention that you need a software to control all this mess.

my choice , finally , was :

1.command station : LENZ LZV100

2.computer interface : Li-USB-Eth by Lenz

3.feedback generator : Lenz LR101

4.feedback occupancy module : Lenz LB101

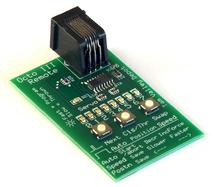

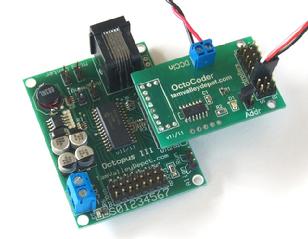

5.switch controller : Octopus III with Octocoder

6.program : Rocrail

Here is , in German , the complete lenz diggital system . Not all parts must be used in order to start over with it . Eveny part you add , you also add another tool for your layout.

Be prepared that all manuals coming with LENZ products are in German . If you want the English version use this link : LENZ USA .

Each LR101 feedback generator can handle up to eight feedback input signals . Each LB101 can detect up to two isolated rails and generate the signal . So each LR101 can be connected with up four LB101 . The occupancy detector LB101 is connected to the LR101 feedback module , the LR101 i sthen connected to the LZV100 . The LZV100 is connected with the Li/Usb/Eth module (via the XpressNet cable) and the Li/Usb/Eth module is then connected to the PC .

As described before , for a pc operated layout you will defenately need a program . I chose the ROCRAIL which seemed very easy to understand and will all the utilities I need .

The webpage of ROCRAIL is here .

First read the step-by-step manual very carefully and then start playing with it . Of course , it provides a virtual utility with which you can test every change you make .

But what is computer control ?

It is a series off connected devices from train to the computer in order them to communicate to each other .

The computer generates the commands which are transfered through connction dvice to the command station and then to the rails and finally to the dcc decoder inside the locomotive.The locomotive generates current draw that is tracked on the tracks using the feedback device which sends info back to the Command station which also sends feedback back to the computer.

Finally the computer arranges its choices according to the feedback and the saved preferences (loco proirity etc)

I chose thse solution of Lenz electronics which provides stable , clear and efficient result .

Moreover not to mention that you need a software to control all this mess.

my choice , finally , was :

1.command station : LENZ LZV100

2.computer interface : Li-USB-Eth by Lenz

3.feedback generator : Lenz LR101

4.feedback occupancy module : Lenz LB101

5.switch controller : Octopus III with Octocoder

6.program : Rocrail

Back view of the Lenz Command station . Comparing with the Roco black box it seems more rigid . far better materials(aluminum) and more expensive result.

Front side of a Lenz lzv200 same as the LZV100 I purchased .

Be prepared that all manuals coming with LENZ products are in German . If you want the English version use this link : LENZ USA .

Each LR101 feedback generator can handle up to eight feedback input signals . Each LB101 can detect up to two isolated rails and generate the signal . So each LR101 can be connected with up four LB101 . The occupancy detector LB101 is connected to the LR101 feedback module , the LR101 i sthen connected to the LZV100 . The LZV100 is connected with the Li/Usb/Eth module (via the XpressNet cable) and the Li/Usb/Eth module is then connected to the PC .

As described before , for a pc operated layout you will defenately need a program . I chose the ROCRAIL which seemed very easy to understand and will all the utilities I need .

The webpage of ROCRAIL is here .

First read the step-by-step manual very carefully and then start playing with it . Of course , it provides a virtual utility with which you can test every change you make .

-Quakenbruck-1943-01.jpg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)